For over three decades, Deeps Texstyles Pvt. Ltd. has been producing sustainable textiles made-ups for global brands — from organic cotton fabrics to finished apparel, home textiles and bags.

Our certified factories in India combine traditional craftsmanship with modern, compliant manufacturing to deliver quality, consistency and ethical integrity at scale.

Delivering sustainable textiles — responsibly made in India for the world.

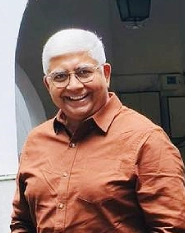

Mr. Deepangshu Ghosal

Mr. Deepangshu Ghosal